What We Can Do

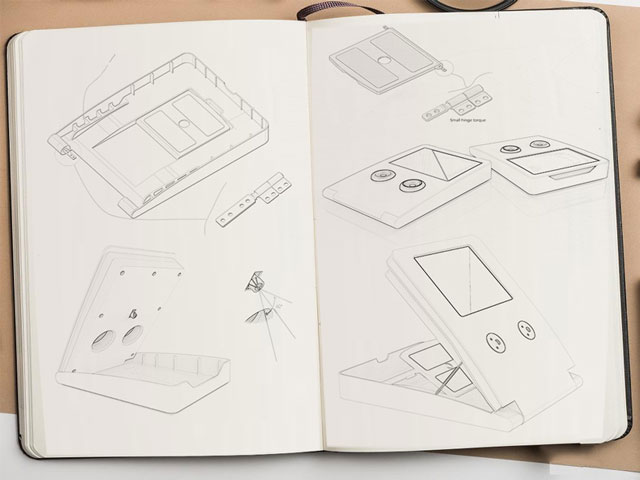

Research and development

All innovations begin with an idea. A thought, a wish, a ‘what if’ … As an expert in injection moulding and the broad range of possibilities in plastics processing, we will gladly think along with you even at the early stages of the development process. Because no matter how small or large the component is, it will always be part of a bigger picture.

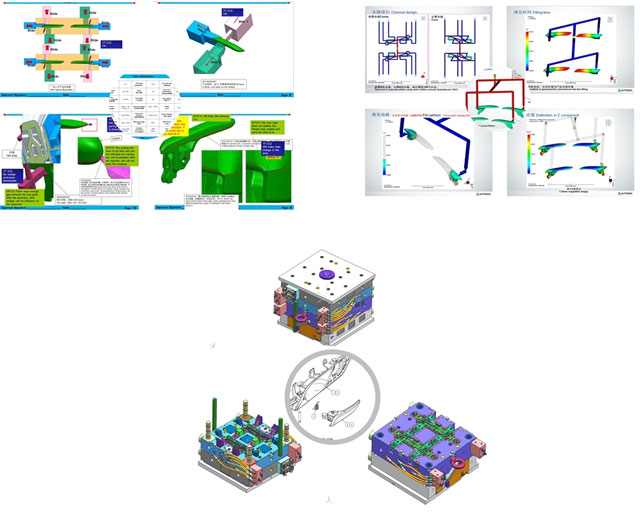

Mold design

Arktech Mold specializes in injection mold building,with the capability to design and build multiple cavity injection molds, injection mold repair, injection mold engineering changes and injection mold maintenance services using the latest innovations in mold making technology, using Cimatron software for design, CAM programming and electrode creation, with hi-speed milling capabilities and wire and sinker EDM capabilities all using FCS integrated locating clamping systems. We also have the latest laser welding capabilities.

Mold manufacturing

Arktech Mold is one of the most-professional middle-size mold maker withc successfully exported more than 1500 high quality mold. We are familiar with different tooling standard, such as Hasco, DME. Our full service on-site tooling room allow Timesplastics to not only build prototype and production molds for our customers, but also provide for prompt attention to any problem that might arise on production floor. Each of our mold makers has a workstation tied into the network with the lastest CAD/CAM sofeware at their disposal.

Injection production

Injection moulding at Arktech Mold means precision work from less than 2 grams to more than 2.5 kilograms. With a clamping force ranging from 25 to 480 tons, we can offer our customers endless possibilities!

Co-creating also means that we seek cooperation with suppliers of raw materials. That makes Arktech Mold a powerful partner for you in the development of injection-moulded parts!

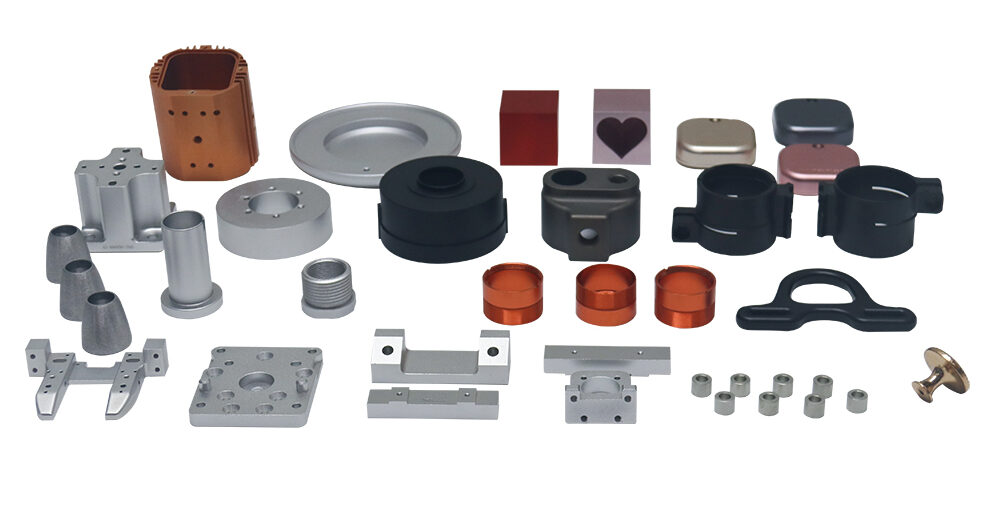

Metal CNC machining

The team at Arktech are highly skilled with experience in the industry of non-standard spare part, specialized in providing customized metal CNC milling turning products processing including Broaching, DRILLING, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM.

Materials: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

Surface treatment: Anodized,Brushing,Polishing,Chroming,Plating,Laser engraving,Silk printing

Our wide range of CNC machinery provides our customers with a one stop shop for all of their machined components.

Rapaid prototype

Cast urethane parts are often compared to injection molding materials. For example, a stiff urethane cast part may be described as

“polycarbonate-like,” and a more flexible plastic may be “polypropylene-like.” We group our urethane materials into general categories to help you make quicker decisions and get the best performance on your project. The list below describes the categories of materials and technical examples when selecting polyurethanes.

Secondary operation

Although the injection moulding of plastics and LSR is the basic work of Arktech Mold, we increasingly find that secondary operation and assembly operations are required. These range from panting, printing, ultrasonic welding, laser welding, assembling products or subassemblies and and packaging to the press-fitting of bearings or inserts and the application of foam or double-sided tape. It’s all possible in our own assembly department and strategic partner.

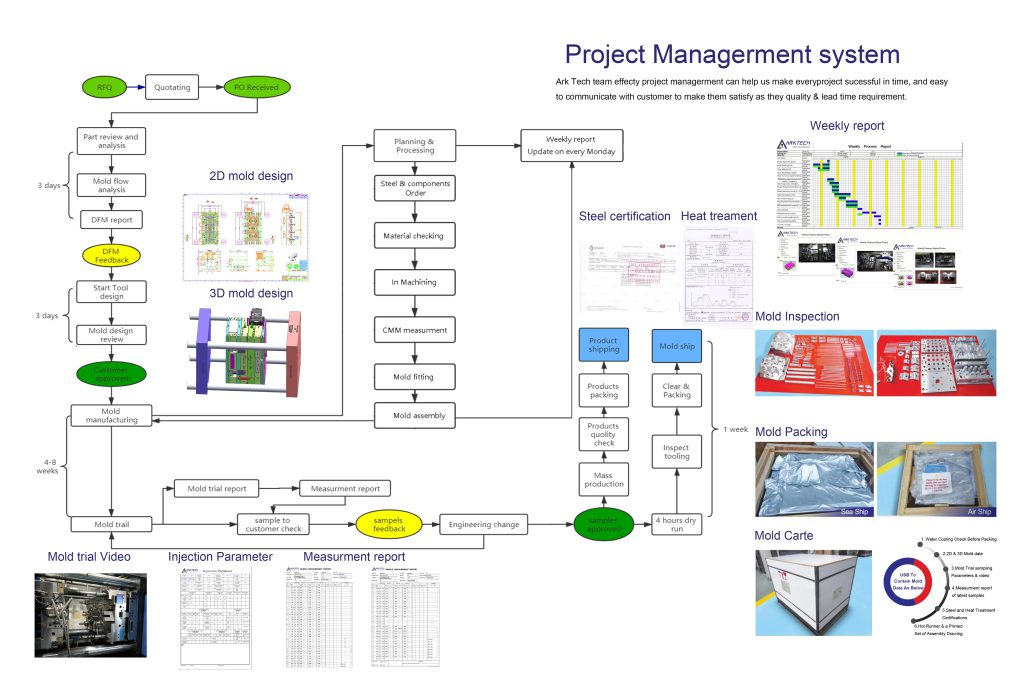

Project Managerment

The members of the project “team” include one project manager, one CNC team leader, one EDM team leader and one mold assembly team leader. Since these machining groups is the key important to control the quality and lead time. It had a projects schedule in our workshop, let everyone know the progress of each project. If the machining date is later than the plan, then the project manager will make the coordination to put the schedule within plan. By this way, we can guarantee quick and on-time delivery, which wins good testimonials from our customers.

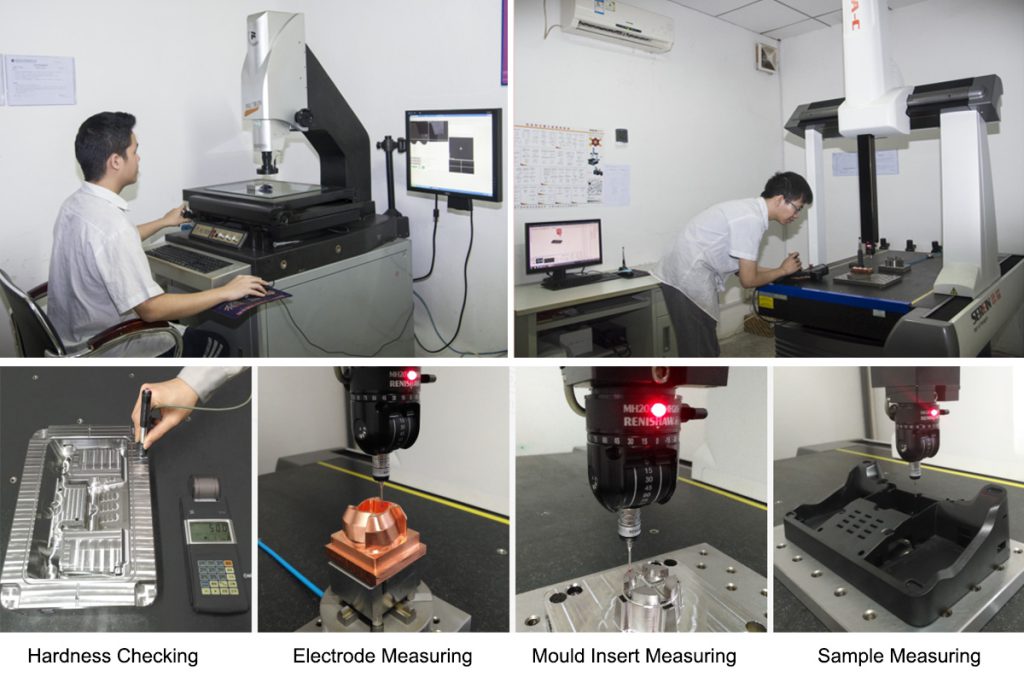

Quality Management

We regard the quality as the life of our company, in order to ensure the excellent quality of the mold. Arktech Mold is equipped with a three coordinate measuring instrument, two-dimensional projector, hardness detector, depth gauge and other high- precision measuring equipment . From mold steel hardness checking to electrodes, mold inserts, samples size measuring, we strictly control the quality, to make customers reassured.