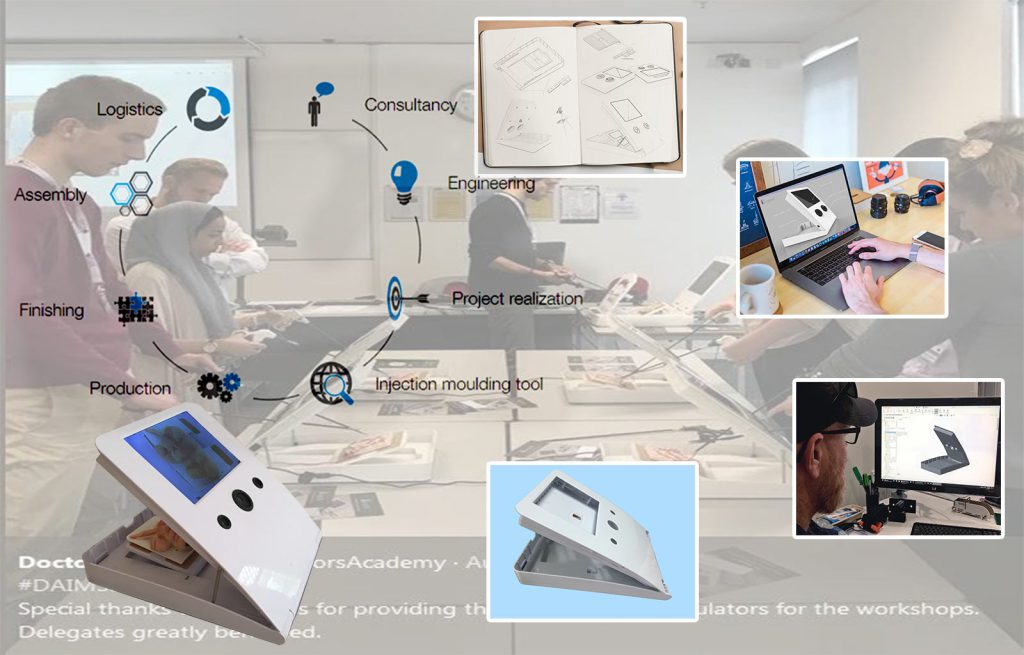

Case Study

Medical device

laparoscopic simulator

The most effective for individual laparoscopic training

- Idea design, research and development

- 3D mode increase

- Plastics mold building and mass produciton

- Secondary operation and assembly

In Mold Lable

Montion Tracker

The MT MultiTracker 110 has BLE technology from Nordic Semiconductor to ensure compatibility with other Meshtech products. It is detachable to ease access to the battery. It may be attached to equipment of different sorts and provides historical data about the equipment.

- Ideo design, research and development

- As small as possible for battery CR2477, Button, LED and IP 68

- Can change color, logo and nice looking

- 3D mold increase

- IML Plastic mold buiding and mass production

- Secondary operation and assembly

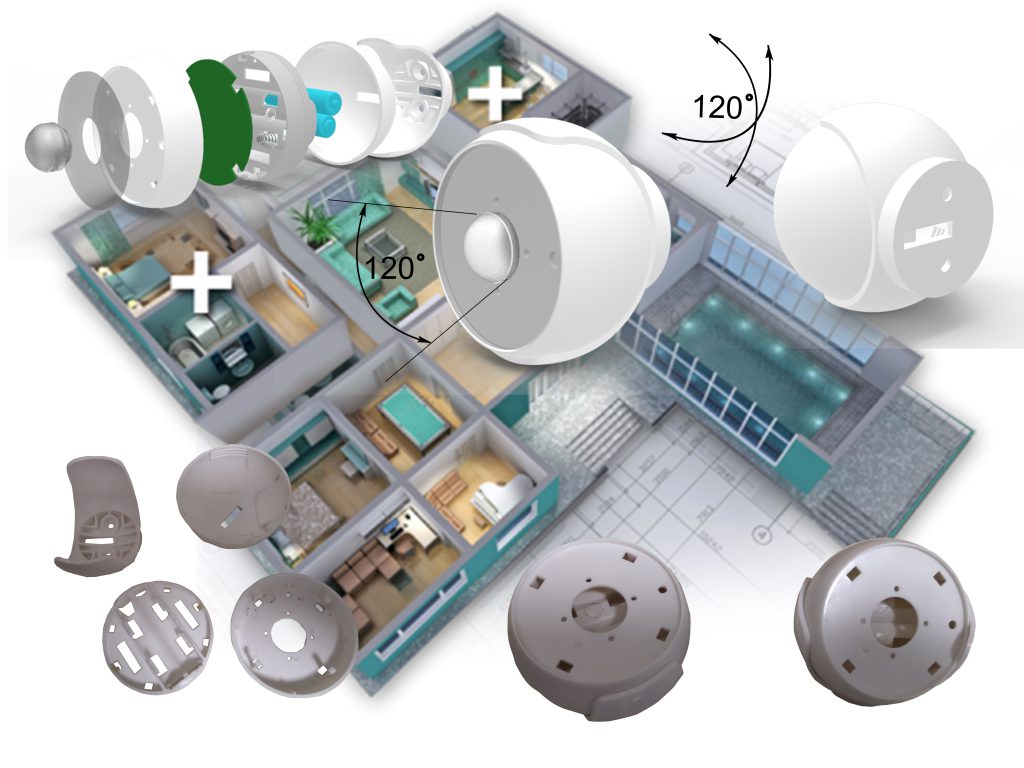

Smart Home

Environmental Sensor

The igh sensor is recognises and monitors occupancy, temperature and light intensity and provides the environmental information to one or many autonomous switch units.

- Idea design, research and development

- Assembly without any screw to save assembly cost

- All assembly by clip and thread

- Connect with battery OR wire

- 3D mode increase

- Plastics mold building and mass produciton

- Printing and assembly

IVaccum Casting

Prototype hander

The new project design from ODM, and customer need make about 100 pcs to test assembly and test marketing, the CNC cost is high, and 3D printing can’t meet fucation require.

- 3D printing first samples

- Check, adjust and polish 3D printing sample

- Use 3D printing samples to make rubber block( samples inside)

- After rubber block cold, and cut it to 2 or more pcs

- Close rubber block and inject plastics resin

- Cut runner from part, and polish part

- Check and packing

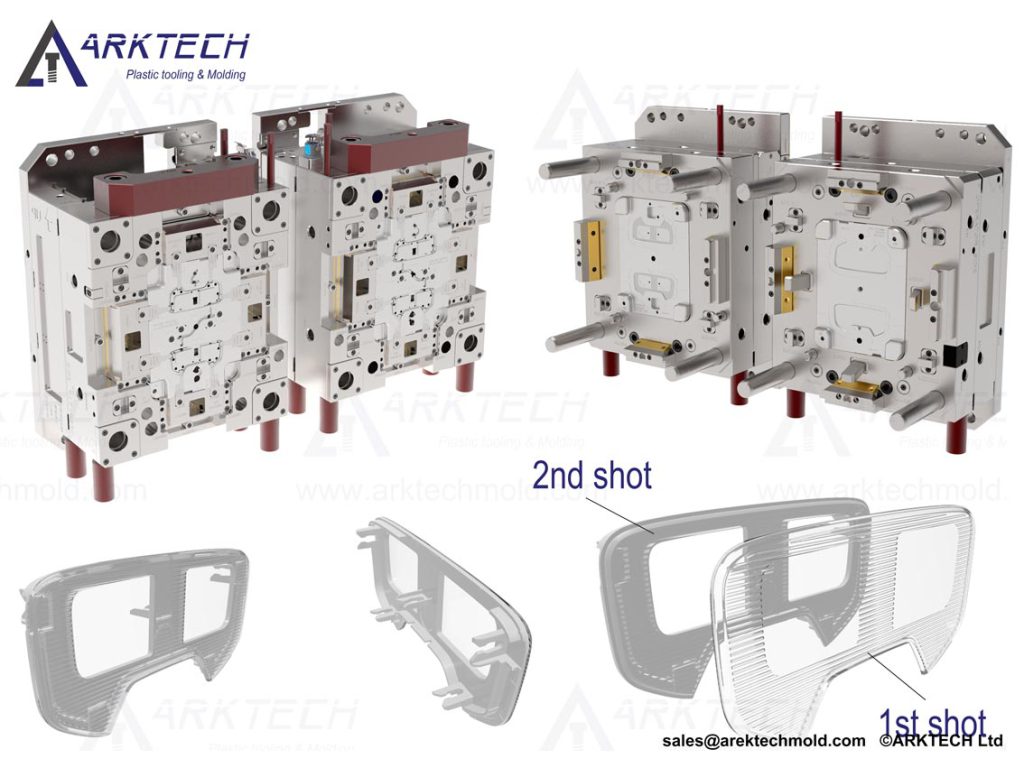

Electronic Product

2K Mold (Bi Material)

There are 2 different material funcation require, one need clear transparecy for light and other can’t transparecy to see anything through it.

- Part review and analysis

- Mold manufacturing

- 2K mold in 2 mold base

- 1st shot: White PC/ABS

- 2nd shot: Clear PMMA

- The windows must be clear

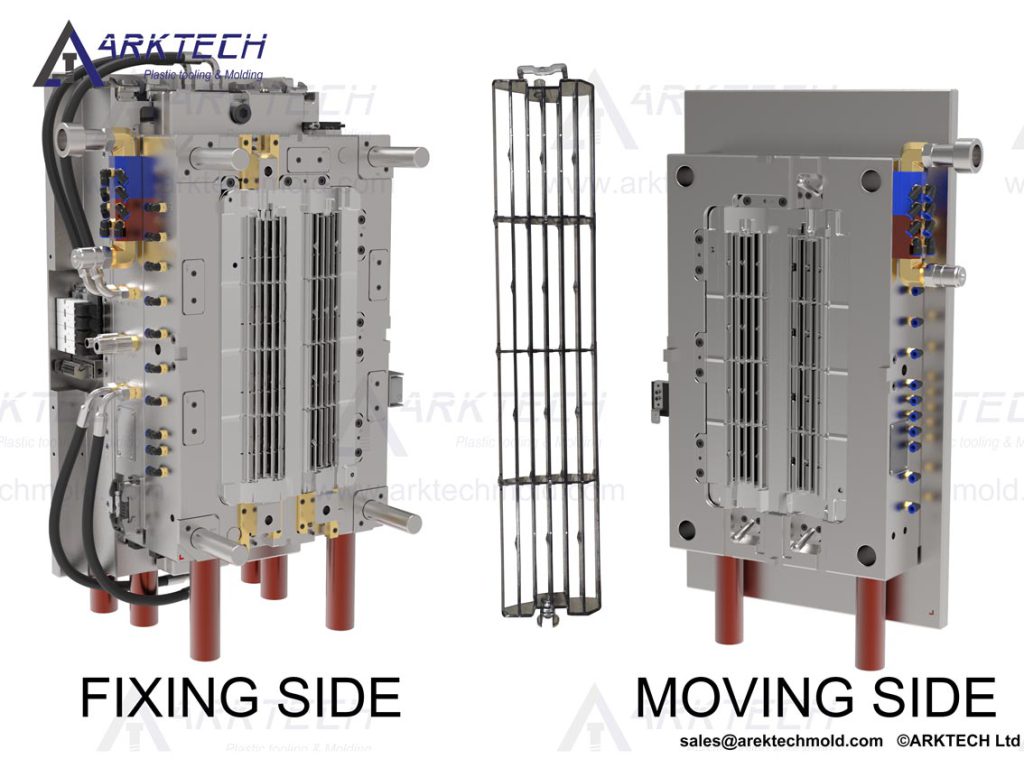

Home Appliance

Eject in Fixing side

Becasue this part can’t have any injection point, ejector mark in visitable surface, need make inject in ejection side

- Part review and analysis

- Mold design & manufactuing

- 3 air valuce hot tip to control filling balance

- Eject in injection side by hydraculic cylinders

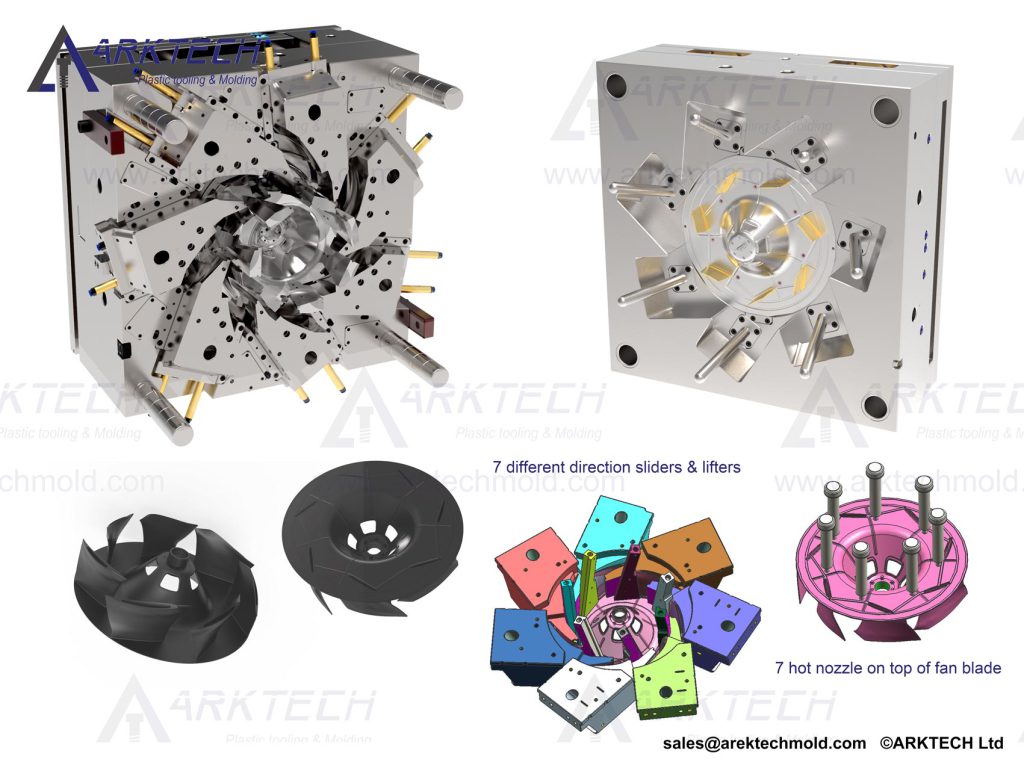

Industrail Part

Fan blade with 7 sliders

There are 7 fan blade in this part, and draft angle is not in core direction, so need make 7 different direction sldiers and lifters

- Part review and analysis

- Mold design & manufactuing

- 7 hot nozzle on top of blade to make filling balance

- 7 different direction sliders & lifters for blade

- Important for each blade all balance and same weigh

- Important for defomation compensate in design

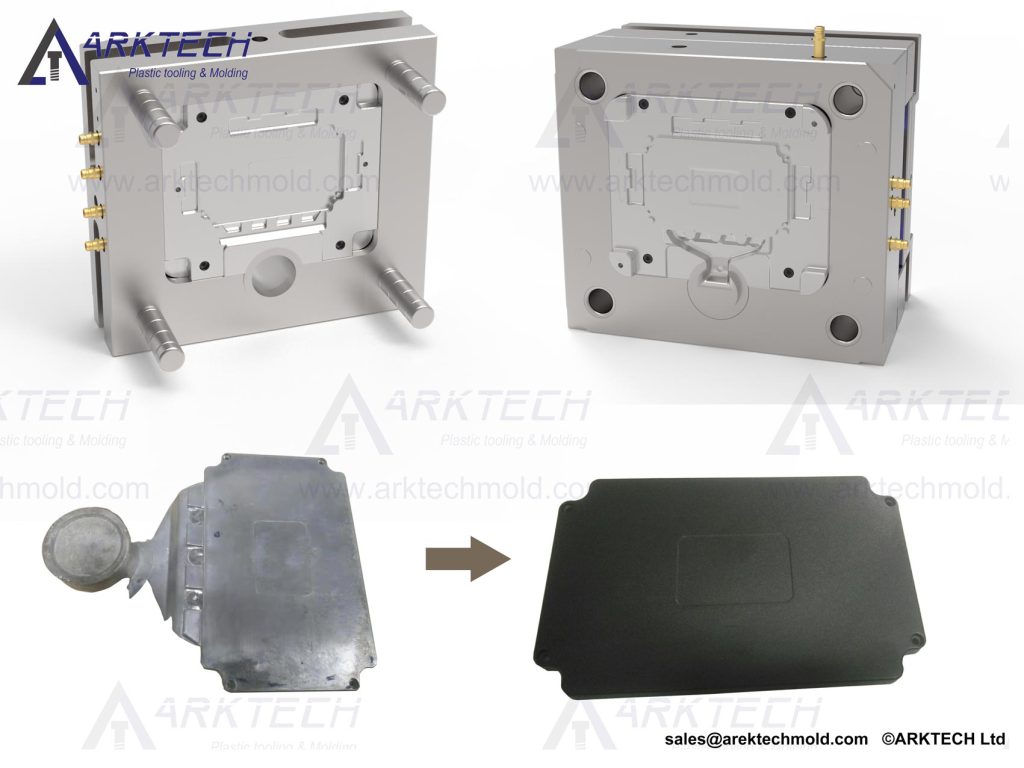

IOT Appliance

Dia Casting

There is IOT device, need nice looking and good heat dispersion. So to make Dia casting tooling for Zinc case.and painting.

- Part review and analysis

- Mold design and manufacturing dia casting tooling

- Produce Zinc parts

- Cut runner and polish burrs

- Sand blasting

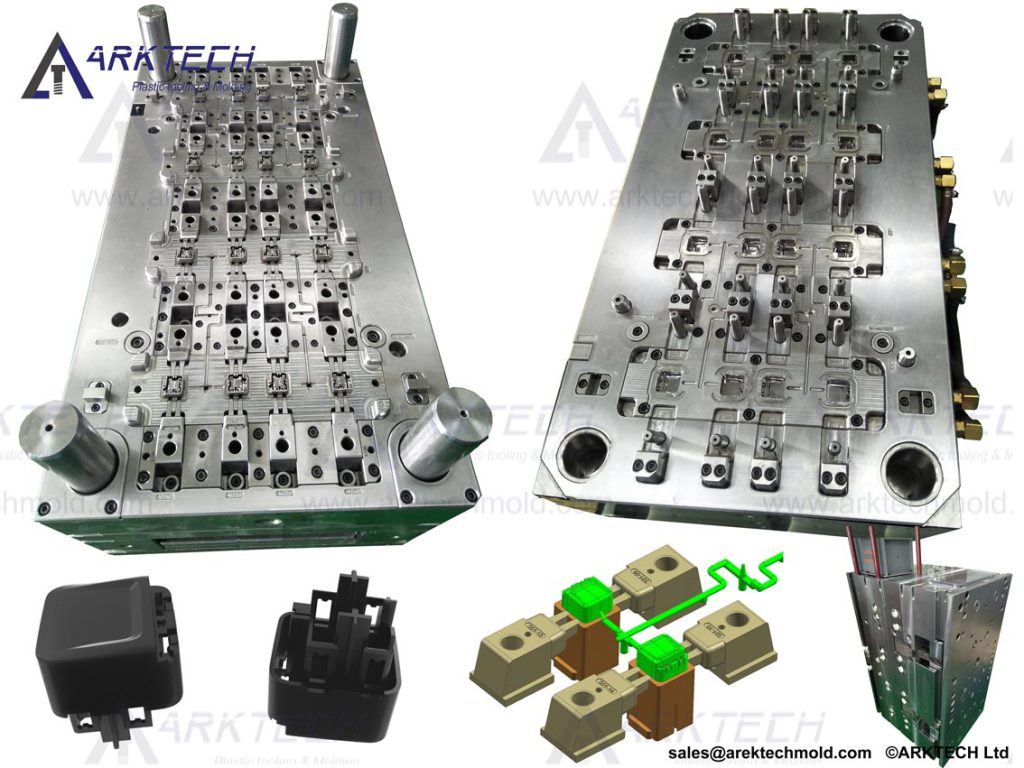

Homehold Appliance

Multi Cavity Mold

There is very big quantity require for this part, so customer need make multi cavity mold for high valuem production to save production cost.

- Part review and analysis

- Mold design & manufactuing

- Total 16 cavity with 2 slider for each cavity

- 4 hot nozzle to cold runner

- Each cavity filling must balance in 3%

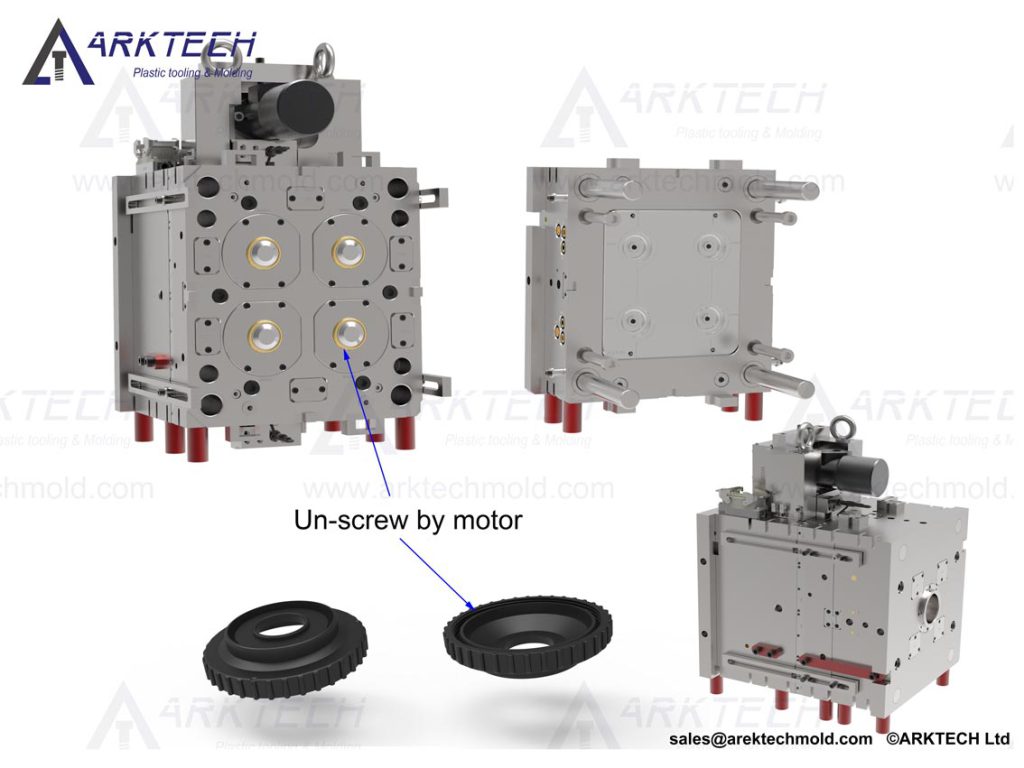

Industrail Part

Un-screw Mold

There is thread inside part for assembly, need production by automotive

- Part review and analysis

- Mold design & manufactuing

- 1 motor for 4 cavity with un-screw inserts

- Un-screw parts before de-molding by motor

- Cold runner to 3 pin gate for each cavity